Introduction to the Advantages and Disadvantages of Several Control Methods for Brushless Motors-Brushless Motor Scheme

Time:2023-07-23

Views:816

As we all know, brushless DC motors are developed on the basis of brushless DC motors. Brushless motors have the advantages of stepless speed regulation, wide speed range, strong overload capacity, good linearity, long service life, small size, light weight, and large output. They effectively solve a series of problems that exist in brushless motors.

Due to the lack of carbon brushes for automatic commutation in brushless motors, it is necessary to use an electronic commutator for commutation. So the brushless DC motor driver is responsible for achieving this electronic commutation function.

There are currently three mainstream control methods for brushless motors:

1. Square wave control:

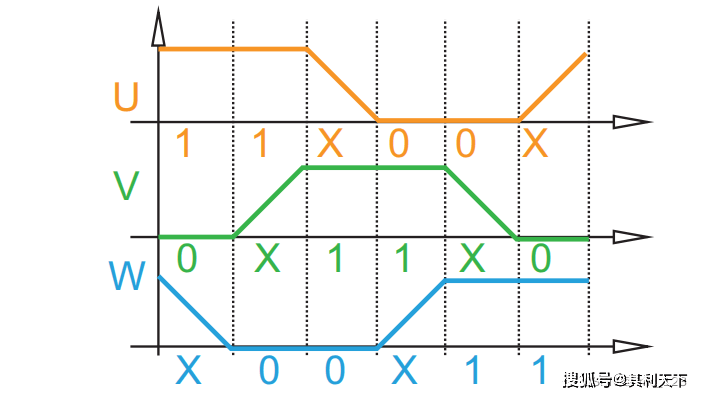

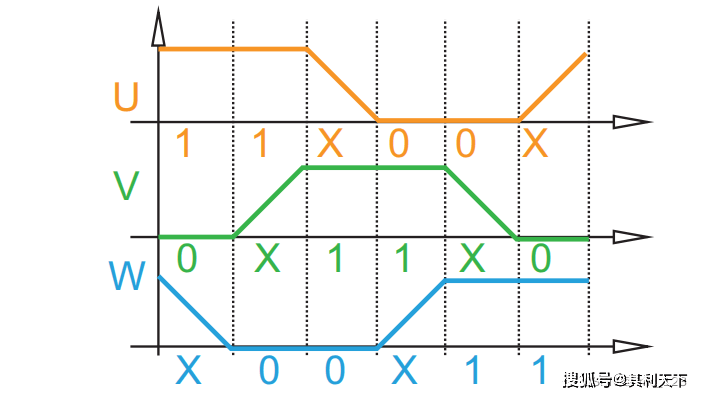

Also known as trapezoidal wave control, 120 ° control, 6-step commutation control

The advantages of square wave control method are simple control algorithm, low hardware cost, and the use of ordinary performance controllers can achieve higher motor speed; The disadvantages are large torque fluctuations, presence of certain current noise, and inability to achieve maximum efficiency. Square wave control is suitable for situations where there is not a high requirement for motor rotational performance. Square wave control uses Hall sensors or sensorless estimation algorithms to obtain the position of the motor rotor, and then performs 6 commutations (every 60 ° commutation) within a 360 ° electrical cycle based on the rotor position. Each commutation position motor outputs a specific direction of force, so it can be said that the position accuracy of square wave control is electrical 60 °. Due to the fact that the phase current waveform of the motor is close to a square wave under this control method, it is called square wave control.

2. Sine wave control:

The sine wave control method uses an SVPWM wave, which outputs a 3-phase sine wave voltage and the corresponding current is also a sine wave current. This method does not have the concept of square wave control commutation, or assumes that an infinite number of commutations have been carried out within an electrical cycle. Obviously, compared to square wave control, sine wave control has smaller torque fluctuations and fewer current harmonics, making it feel more "delicate" to control. However, the performance requirements of the controller are slightly higher than square wave control, and the motor efficiency cannot be maximized.

3. FOC control

Also known as vector frequency conversion or magnetic field vector oriented control

Sine wave control achieves voltage vector control, indirectly controlling the magnitude of current, but cannot control the direction of current. The FOC control method can be considered as an upgraded version of sine wave control, which achieves current vector control, that is, vector control of the motor stator magnetic field.

Due to the control of the direction of the motor stator magnetic field, it is possible to maintain the motor stator magnetic field and rotor magnetic field at a constant angle of 90 °, achieving maximum torque output at a certain current. The advantages of FOC control method are: small torque ripple, high efficiency, low noise, and fast dynamic response; The disadvantage is that the hardware cost is high, there are high requirements for controller performance, and the motor parameters need to be matched.

So, which approach is more suitable for future development? FOC is currently the best choice for efficient control of brushless DC motors (BLDC) and permanent magnet synchronous motors (PMSM). FOC accurately controls the size and direction of the magnetic field, resulting in stable torque, low noise, high efficiency, and high-speed dynamic response of the motor.

Due to the obvious advantages of FOC, many companies have gradually replaced traditional product control methods with FOC in many applications.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |