The battery booster IC can cleverly extend the service life of button lithium batteries in wireless applications

Time:2024-03-14

Views:248

Author: Art Pini

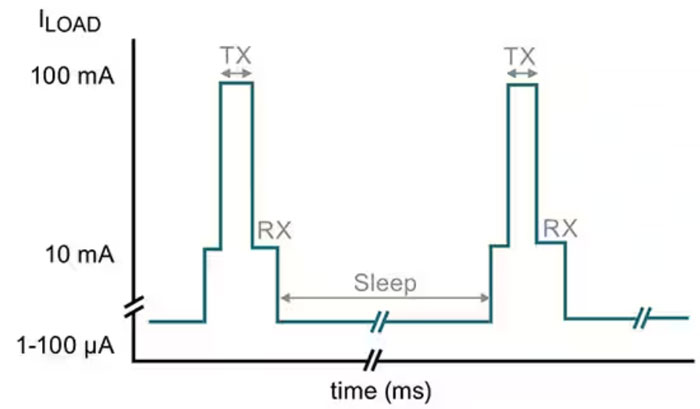

The Internet of Things (IoT) has accelerated the popularity of wireless sensors. Whether used for consumption, healthcare, industry, or agriculture, wireless sensors must be compact, lightweight, and have a long battery life. In addition, such devices can also cause intermittent high current loads on the power supply during transmission and reception modes. For example, sudden transmission consumes 100 mA of current, while receiving operation can consume 10 mA of current, and the remaining longer time is spent in low current sleep mode, with current consumption of μ A-level (Figure 1).

Figure 1: Load curve of a typical wireless device, showing the short-term high current demand for transmission and reception operations (transmission: 100 mA, reception: 10 mA), as well as longer periods of low current sleep mode. (Image source: Nexperia, modified by the author)

The transmission or reception work cycle typically lasts for tens of milliseconds, while the device is typically in sleep mode for hundreds of seconds. Although the average current is lower due to a small duty cycle, high peak currents can cause problems.

Button lithium batteries have a small size and high energy density, but providing a current of over 10 mA significantly shortens their lifespan. These types of batteries also have relatively high internal resistance, making them inefficient in providing the aforementioned high currents. For example, the internal resistance of the new button battery is about 10 Ω. Providing a current of 100 mA will cause a voltage drop of 1 V on the internal resistance of the battery. Under such heavy loads, the chemical reaction rate of the battery can also lead to a decrease in output voltage. In addition, as the battery ages, the internal resistance will also increase. One possible alternative is to use alkaline batteries. Alkaline batteries have a higher rated peak current, but the disadvantage is that they are much larger than button batteries.

Battery booster can extend the lifespan of button batteries

Nexperia has developed a clever solution to support button batteries. The button battery life enhancer integrated circuit (IC) series isolates the high current demand of button batteries from RF circuits. This approach can extend the battery life in wireless sensor applications, achieving smaller and lighter packaging while maintaining excellent battery life.

These enhancers are designed with two DC-DC conversion stages. The first conversion stage draws energy from the button battery with low current to charge the capacitive energy storage element, achieving a higher voltage than the battery. After the energy storage capacitor is fully charged, the second DC-DC converter will adjust the output voltage as needed to provide energy to intermittent loads. Button batteries are never affected by the high current required by external loads, thereby extending their lifespan.

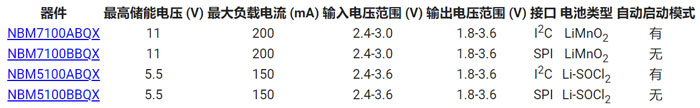

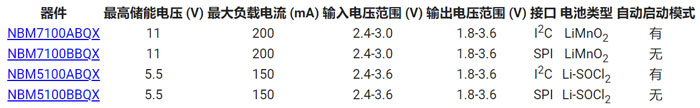

With this method, in applications with high intermittent load currents, the battery life can be extended by 4 to 10 times, while the peak output current can be increased by up to 25 times. These devices are divided into two series, which match the characteristics of lithium manganese dioxide (LiMnO2) or lithium sulfite chloride (Li-SOCl2) batteries (Table 1).

Table 1: Characteristics of integrated circuits for NBM5100/NBM7100 series button battery life enhancers. (Table source: Art Pini)

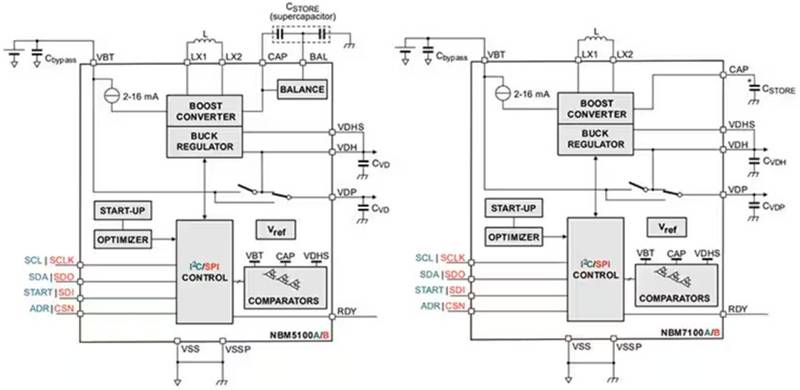

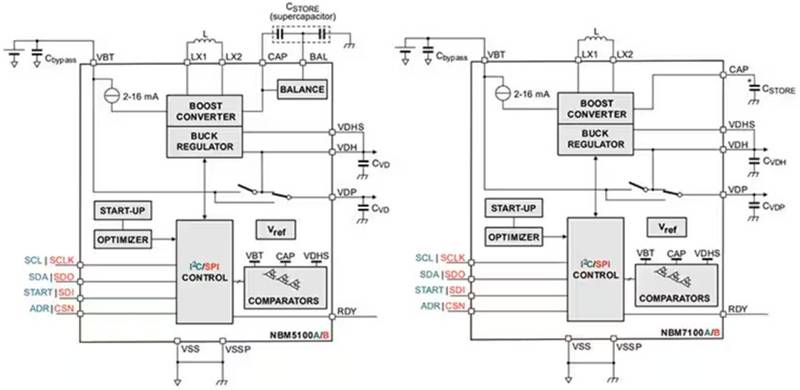

The internal structure of these battery enhancers is similar (Figure 2).

Figure 2: Block diagrams of NBM5100A/B and NBM7100A/B devices, showing that they are functionally similar. (Image source: Nexperia)

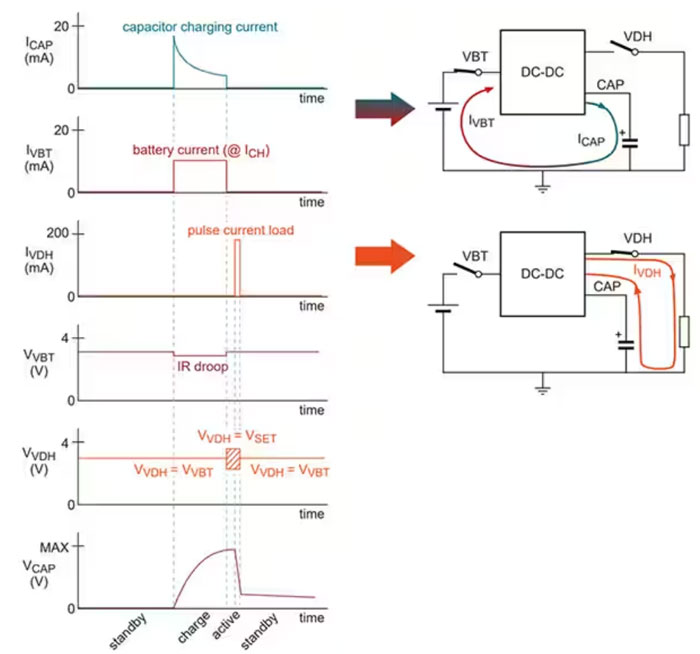

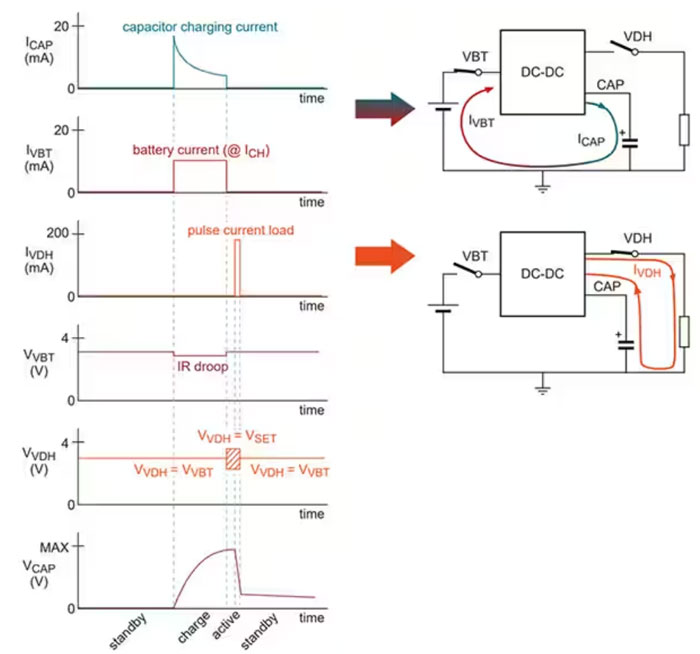

The working mode of these button battery enhancers is also similar (Figure 3).

Figure 3: Voltage and current state curves of NBM5100/7100 during charging (upper right figure) and active load (lower right figure) cycles. (Image source: Nexperia)

The battery booster uses two high-efficiency DC-DC converters to buffer the battery and protect it from the effects of short-term high current load transients. In the first conversion stage, a boost converter is used during the charging cycle. This cycle starts before the heavy load current cycle. When charging, energy is transferred from the battery to an external energy storage capacitor, whose voltage (VCAP) is higher than the battery voltage. The charging cycle draws low constant current (IVBT) from the battery. Due to its internal resistance, low charging current can cause a decrease in battery output voltage (VVBT). After charging the capacitor, the voltage regulator DC-DC converter processes the working cycle and transfers energy from the energy storage capacitor to the output (VVDH), providing high load current (IVDH) with up to 90% efficiency under voltage regulation.

Please note that the battery current consumed during the charging cycle (IVBT) remains extremely low, while the battery current consumed during the working cycle can be ignored. This reduces the repetitive pressure on the battery and expands its available capacity. When not in charging or working cycle, the output will drop to static or standby mode, and the current consumption will be less than 50 nA.

The battery booster IC adopts an adaptive learning algorithm, which can monitor the load pulse characteristics and intelligently optimize the energy transmission and storage of the capacitor. Up to 63 load configuration files can be retained to adjust the charging process.

Booster working mode

The NBM5100/7100 device operates in continuous, on-demand, and automatic modes (NBM5100A and NBM7100A versions only). Continuous mode is used for applications that require immediate response to transient loads. The energy storage capacitor is charged, and the DC-DC converter is idle. The voltage of the energy storage capacitor is monitored and refreshed as needed. After receiving the work order, the energy storage capacitor immediately provides a stable output. After providing the required energy to the load, the energy storage capacitor is recharged. After fully charging, set the ready signal.

On demand mode is used for applications that require the longest battery life. This mode is activated in standby mode. On demand mode uses I/O interfaces to set appropriate bits for startup. Energy storage capacitors charge when needed and provide stored energy according to the indication of the ready signal.

Automatic mode uses startup signals to start on-demand work, without using I/O interfaces. The ready signal indicates that the energy storage capacitor is fully charged and available.

The NBM5100/NBM7100 series uses a serial I/O interface for control. The NBM5100ABQX and NBM7100ABQX devices use I2C interfaces, while the NBM5100BBQX and NBM7100BBQX ICs are equipped with SPI interfaces.

These battery life extenders can monitor the number of charging cycles and report the remaining power of the button battery. These devices report the battery charging status through the battery meter register provided by the serial interface.

The NBM5100/NBM7100 series button battery life extender adopts a SOT763-1 (DHVQFN16) 16 pin package, with a working temperature range of -40 to+85 ° C.

Nexperia provided NEVB-NBM5100A-01 and NEVB-NBM7100A-01 evaluation boards for NBM5100ABQX and NBM7100ABX, respectively. By using these evaluation boards, it is possible to quickly and conveniently evaluate battery boosters. They can be connected to the circuit board under development and controlled from a PC using a graphical user interface (GUI) via USB connection.

epilogue

The NBM5100/NBM7100 battery enhancer can extend the lifespan of button lithium batteries in wireless IoT applications with high transient loads. Without such enhancers, these applications may require the use of much larger AA or AAA batteries. Therefore, these battery enhancers are an excellent way to shrink device size and reduce costs.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |