Motor driven control vehicle specification chip solution

Time:2024-01-06

Views:400

Accelerate the development of automotive specification chips and actively expand the automotive electronics market

Fengyi Technology focuses on the research and development of high-performance motor drive control chips and control systems, and has been deeply involved in the BLDC field for a long time. With the advantages of independent research and development technology and system level services, the product line of motor main control chips continues to grow, becoming a leading enterprise in the domestic BLDC control chip field. BLDC is increasingly widely used in the field of intelligent control for household and industrial use. This type of motor has a large number of control parameters, complex control algorithms, and high requirements for computing speed, making research and development very difficult. The core technology team of Fengyi Technology has built a complete technical system in chip technology, motor drive architecture algorithm, and motor technology, and has achieved multiple core technologies, At present, the company has obtained a total of 107 authorized patents and software copyrights, 51 invention patents, including 8 overseas invention patents.

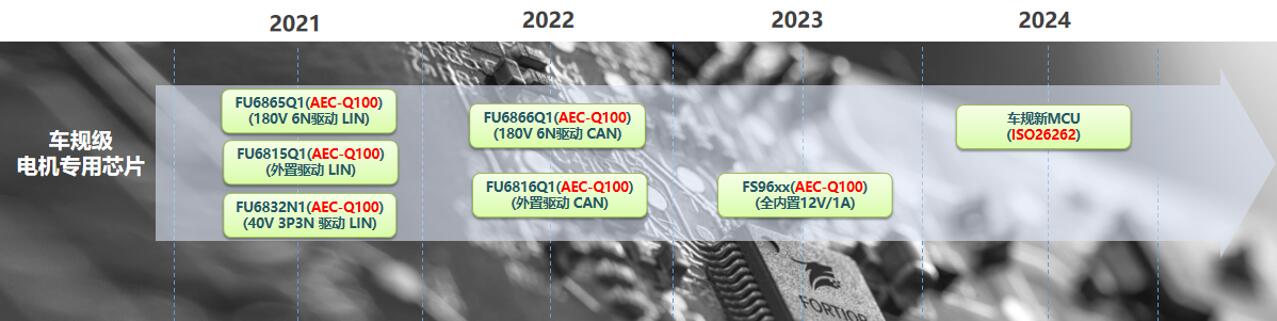

Fengyi Technology is actively expanding into emerging application markets and increasing its market expansion in the automotive electronics field. The company‘s independently designed and developed dedicated IC is gradually promoting product testing and application in the automotive market. Fengyi Technology‘s dedicated MCU chip FU6832N1 has passed AEC-Q100 vehicle specification certification. Currently, the company is collaborating with T Ü V Rheinland Group in Germany on the ISO 26262 functional safety project, The process system certification and product certification of ISO 26262 are highly recognized in the automotive industry, and this standard is widely recognized as a necessary condition for chips to be used in mass production of safety related components in vehicles. The implementation of the ISO 26262 project will help Fengtian Technology improve the safety and reliability of chip products and strengthen its comprehensive competitiveness in the automotive market.

Fengfeng Technology Vehicle Class MCU Series

MCU, also known as microcontroller, integrates the CPU, memory, I/O ports, serial ports, timers, interrupt systems, special function registers, and other components of a computer into a single chip to achieve calculation and control of the product. Vehicle mounted MCU is the core component of automotive electronic control units, and with the acceleration of automotive electronics, the demand for automotive grade MCU in China has expanded.

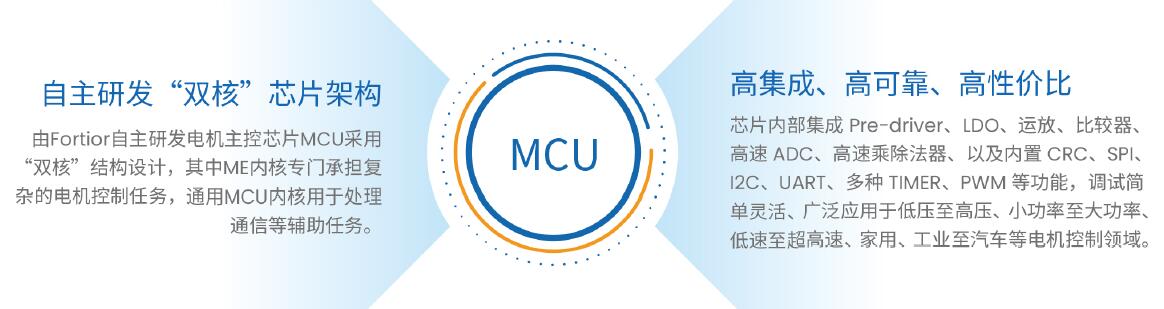

The motor drive control MCU independently developed by Fengyi Technology adopts a dual core structure design, which has the characteristics of high integration, high reliability, and high cost-effectiveness

1. Dual core design, 8051 core+ME core (FOC control module, square wave control module, MDU supports multiplication and division/low-pass filter (LPF)/trigonometric function calculation, proportional integral/differentiator (PI/PID));

2. Built in LDO, operational amplifier, and comparator effectively save costs and layout space;

3. Built in Pre driver driver driver;

4. Square wave control supports automatic commutation, wave by wave current limiting, and supports HALL and BEMF position detection;

5. Support control of both non sensing and sensing FOC;

Introduction to the Special Chip for Motor Controller of Fengfeng Technology Automotive

The FU6832N1 chip integrates ADC, AMP, DAC, LDO, DMA, Pre driver, etc. internally, and integrates the ME motor control core, including hardware FOC function module, square wave function module, PI, LPF, MDU, etc. Chip packaging QFN32_ 4X4mm, the chip has passed AEC-Q100 certification. Mainly targeting low-power brushless motors and compact motors such as water pumps, seat fans, air intake grilles, etc.

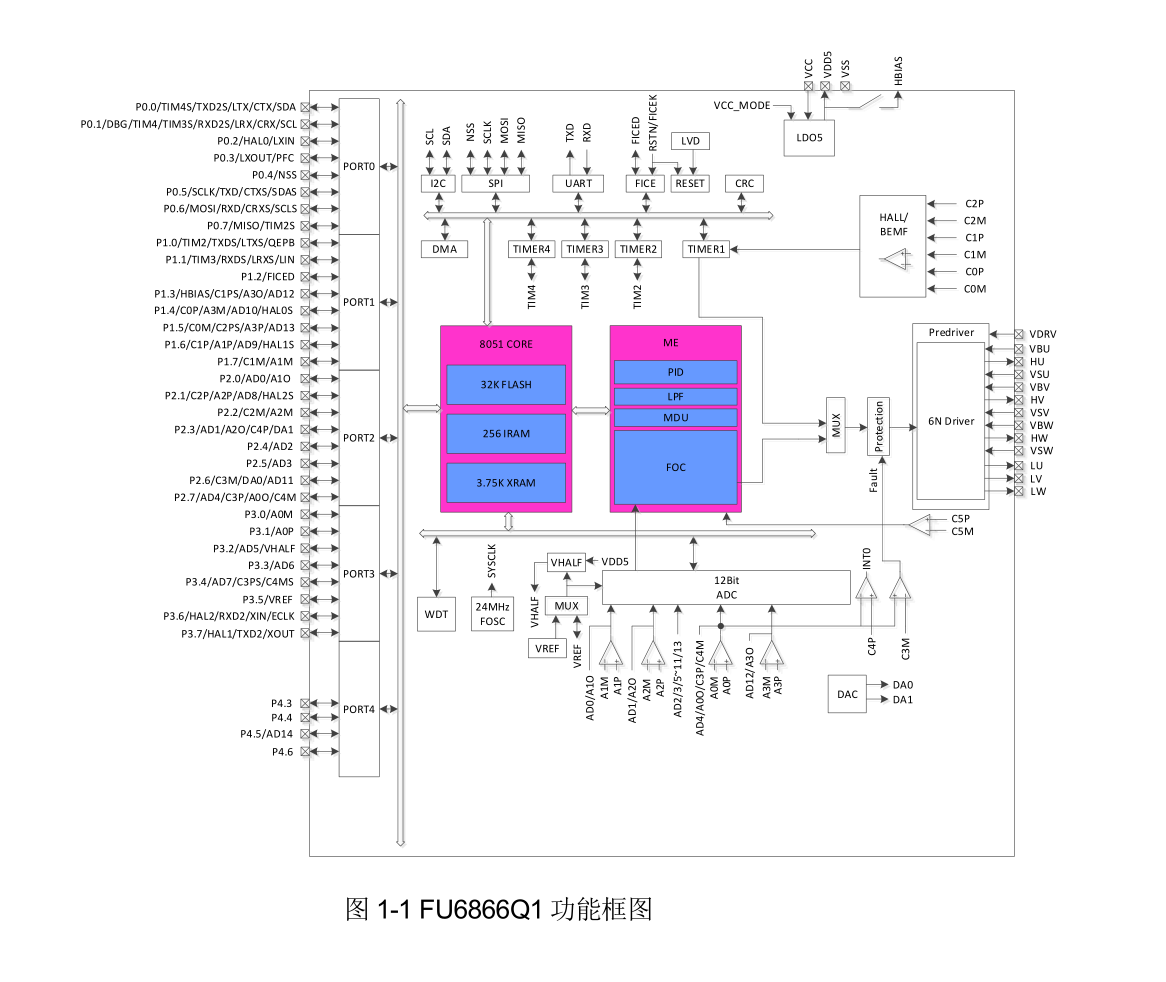

FU6866Q1 is a highly integrated specialized IC chip developed and designed for the automotive motor market by Fengyi Technology in 2022. It integrates LIN communication, LIN transceiver, CAN communication, built-in Pre driver, high-voltage LDO, high-speed comparator, high-speed operational amplifier, ADC, DAC, CRC, I2C, UART, DMA, TIMER and other functional modules. Different control schemes suitable for DC brushless motors, such as non inductive FOC, inductive SVPWM, and inductive/non inductive square wave. AEC-Q100 certification is currently in progress.

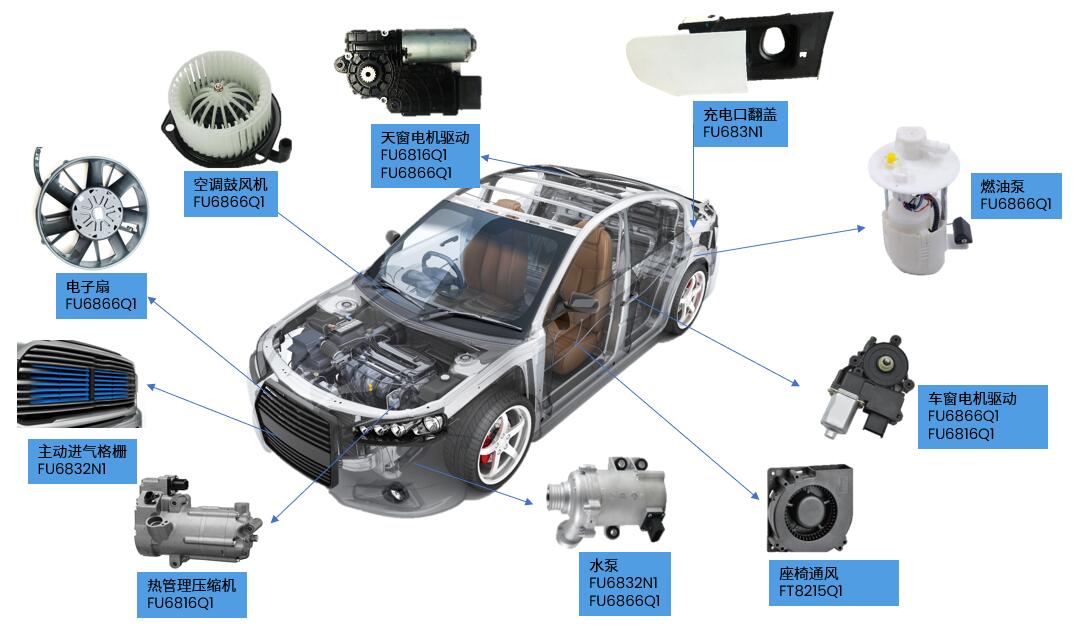

The temperature level of FU6866Q1 is Grade 1, and the chip operates at TJ (-40-150 ℃) and TA (-40-125 ℃). It can be widely used in the field of motor control related to vehicle body control, including thermal management systems, water pumps, electronic fans, glass lifting control, seat motor control, tailgate motors, etc.

Based on the high integration of automotive chips in the field of brushless motor control, Fengyi Technology provides comprehensive products and technical support, which can quickly and efficiently complete project debugging. Internal universal kernel that can effectively match customers for personalized design

Application Plan 1: Automotive Active Grille

Currently, there are more and more models with active air intake grilles. The main function of the active intake grille is to close it during low-temperature driving and cold starting, so that cold air does not directly impact the radiator for forced cooling, thereby quickly increasing the engine‘s water temperature. It can also control the intake volume and wind resistance during high-speed driving, saving fuel.

The characteristics of AGS motor control can be divided into the following aspects

1. High integration: Due to the small size of the AGS controller itself and the fact that most of the internal parts of the motor are gear reduction mechanisms, the actual available space of the entire motor is very small, which requires high integration of the motor MCU controller;

2. Senseless BLDC control position closed-loop: AGS needs to use position closed-loop to control the opening and closing degree of AGS during operation, so the motor needs to record the number of motor runs during operation to obtain the position information of the motor;

3. Operating torque control: During normal operation, the AGS will output and drive at the rated driving torque. When the current torque cannot make the grille run to the specified position during the execution process, the actuator will automatically enter torque enhancement mode to try to break through the obstruction.

4. Position initialization self-learning: When in the AGS initialization state, it will receive self-learning instructions sent by the ECU. The AGS will learn the positions of the two stop points, fully open and fully closed, and compare them with the preset angle to determine whether there are any problems with the grid, such as jamming or structural damage.

5. Fault detection and protection: AGS actuators should have fault self diagnosis functions, including gate blade structure faults, locked rotor faults, electrical faults, etc.

6. Boot online upgrade function

In addition to the active intake grille, compact motor control is also widely used in other automotive components, such as air conditioning vents, charging port covers, and valves

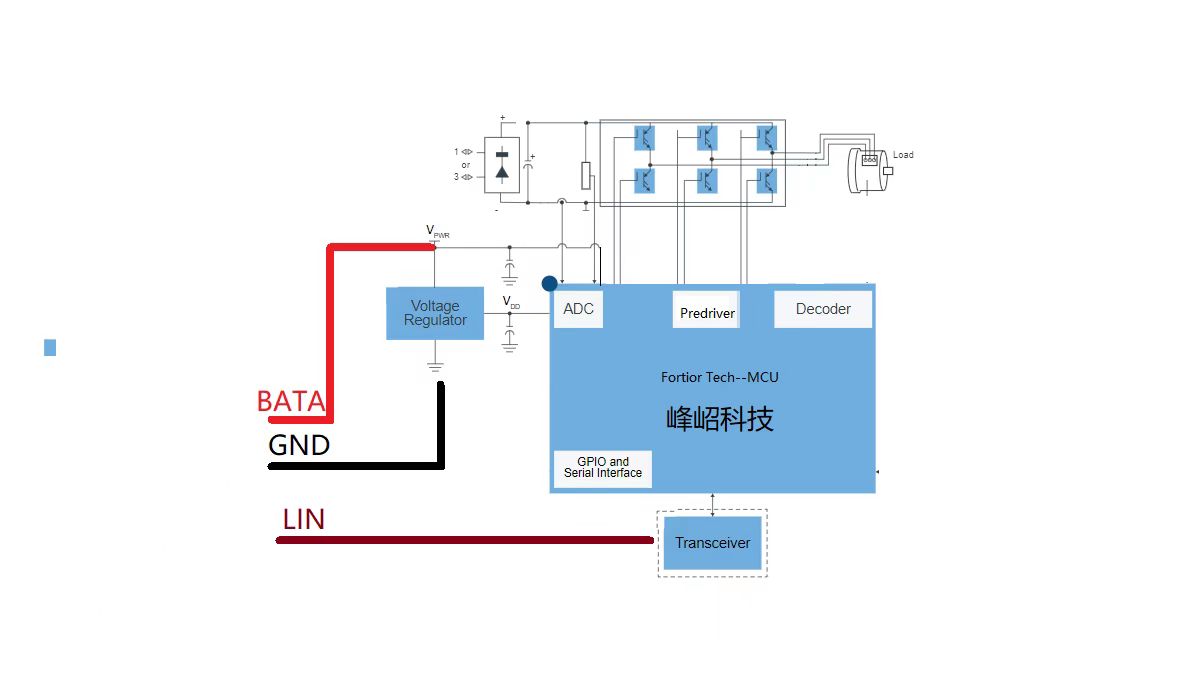

The above figure is a block diagram of a compact motor control solution, where the left side shows the power supply and LIN signal inputs, and the top side of the figure shows the BLDC motor; In actual control, the controller receives a LIN bus signal and enters a wake-up normal working state. During normal operation, the position closed-loop control is used to control the motor to run to the specified position.

Application Plan 2: Automotive Water Pump

The automotive water pump is one of the important components in the automotive thermal management system, and is indispensable in fuel vehicles and new energy vehicles.

The characteristics of automotive water pump control can be divided into the following aspects

1. High control efficiency: During testing, the water pump needs to reach the standard flow rate and head at the specified power, so higher control efficiency is important for water quality;

2. Low noise and low vibration: FOC can effectively reduce the working noise and vibration of water pumps, while improving their efficiency.

3. Multiple types of abnormal protection: idle, overvoltage, undervoltage, overcurrent, locked rotor, over temperature, power reverse protection, etc.

Fengfeng Technology‘s automotive water pump solution covers water pumps in various power ranges of automobiles, with a power range of 40W~500W. It uses an insensitive FOC to drive motors with high efficiency, and uses a speed and power loop to control motor operation stability and low noise. The control methods include PWM speed regulation and LIN bus control. At the same time, there is comprehensive fault protection and fault handling to ensure the safe operation of the motor.

Application Plan 3: Automotive Fans

Fans are very important electronic components in engine cooling systems and HVAC systems. Car fans include: electronic fan, thermal fan, air conditioning blower, seat ventilation motor, etc.

The control characteristics of car fans vary according to different types:

1. Low noise: The fan motor in the cabin has strict noise requirements.

2. Multiple abnormal protections: forward and reverse wind detection, overvoltage, undervoltage, overcurrent, rotor blockage, over temperature, power reverse connection protection, etc.

Fengyi Technology‘s fan solutions cover various types of automotive fans, with control modes such as inductive/non inductive square wave and non inductive FOC, to meet the design needs of different fans. The use of speed and power loops to control motor operation stability is high, and the noise is low. The speed control methods include PWM speed control and LIN bus control.

Wider range of automotive electronic motor controller solutions

In addition to compact motor controllers, Fengyi Technology also has numerous automotive electronic application solutions, including fans, pumps, brushed motors, compact motors, and so on;

Fans include electronic fans, air conditioning blowers, and seat ventilation fans, which have the advantages of FOC control, reliable starting, low noise, low vibration, and easy debugging;

The pump category includes: water pump, oil pump. Advantages: Using FOC control, low noise, low vibration, high efficiency, and stable flow rate;

Brushing motors include: windows, sunroof. Advantages: high integration and low startup noise;

The compact motor includes: air intake grille, air conditioning outlet, charging port cover and valve, with advantages of high integration and high torque starting;

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |