Introduction to the working principle of BLDC brushless motor

Time:2023-11-29

Views:516

Integrated motor is a special type of motor that is widely used in modern electronic equipment manufacturing due to its compact structure, high efficiency, and smooth operation. Among them, the brushless DC motor is composed of the motor body and the driver, and is a typical mechatronics integrated product. Brushless motor refers to a motor without brushes and commutators (or collector rings), also known as a commutator free motor, with a high frequency of use. This article will focus on the working principle of DC brushless motors and provide a detailed introduction to them.

1、 Working principle of brushless DC motor (BLDC)

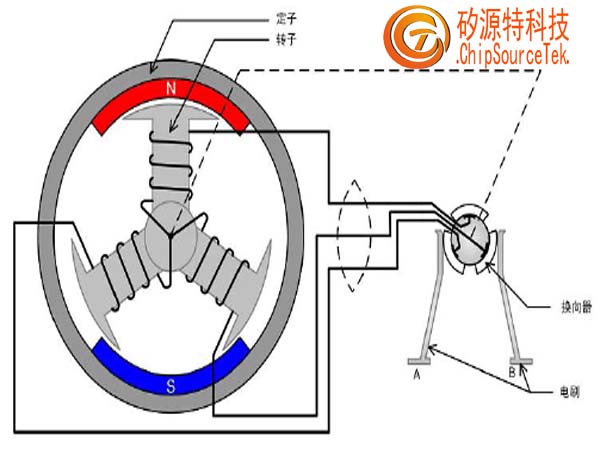

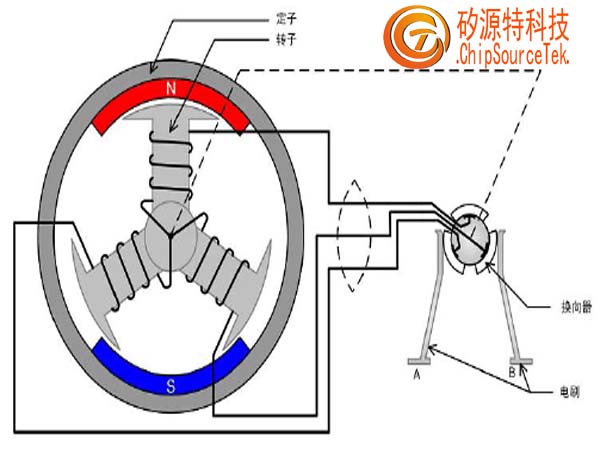

Consider the steps to install three windings in stator A, B, and C. Replace the rotor with a single magnet to make things easier to understand.

When current passes through a coil, a magnetic field is generated, and the direction of the magnetic field lines (i.e. the magnetic poles of the resulting magnet) is determined by the direction of the current.

According to this concept, if a current is sent to coil A, it will generate a magnetic field and attract the rotor magnet. The rotor magnet will have a small clockwise offset and align with A.

If the current is allowed to flow through coils B and C one by one (in this order), the rotor magnet will rotate clockwise.

To improve efficiency, a coil can be wrapped around opposite coils, creating a double attraction. In order to further improve efficiency, two coils can be energized simultaneously, with one coil attracting a magnet and the other coil repelling the magnet. The third one will be idle during this period.

Six different combinations of coils A, B, and C can be used to rotate the rotor magnet 3600 times, as shown in the timing diagram below.

According to the diagram above (or floating), it is always possible to ensure that one phase is positive, one phase is negative, and the third phase is idle. According to the above diagram, there are two switching stages, depending on the input of the Hall sensor.

2、 Construction of DC Brushless Motor

A DC brushless motor is composed of a stator and a rotor. The stator is usually made of materials such as iron core and coils, and its interior includes magnetic field sensors and commutation circuits. The rotor includes permanent magnets, rotor shafts, circulators, and other parts. It is worth noting that the biggest difference between a DC brushless motor and a traditional motor is that it does not have an energized collector brush and a rotating AC motor.

3、 The advantages of DC brushless motors

Due to the use of electronic commutation in brushless motors, they have many advantages compared to traditional brushed DC motors

3.1. No wear (due to lack of brushes)

3.2. High efficiency

3.3. Better speed and torque characteristics

3.4. Longevity

3.5. Low or no operating noise

3.6. Higher speed

3.7. Implementing a fixed-point or floating-point controller using a microprocessor

However, DC brushless motors also have some drawbacks. For example, when operating under high loads, it is easy to experience stall phenomenon; Meanwhile, due to its complex internal structure, maintenance is difficult and the cost is high.

4、 Summary

In summary, DC brushless motors are an integrated motor with broad application prospects. Its working principle is based on the combination of magnetic sensing technology and commutation circuit control, which can achieve efficient and stable operation. However, in the actual application process, it is still necessary to overcome its shortcomings in order to better promote its application development.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |