Development Trends of DoB High Voltage Linear Drive ICs

Time:2023-07-20

Views:832

What is the DoB IC (de powering) solution

DoB (Driver on Board) or Driverless, also known as "de powering", is actually not without a power supply, but a new driving method different from traditional switching power supplies, which is derived from LED characteristics.

DoB IC solutions have many pioneers in the industry, mainly including Seoul Semiconductor, UK LynkLabs, Texas Instruments and Exclara in the United States, and Industrial Technology Research Institute, Interlight and other giants in Taiwan. However, China started relatively late due to insufficient R&D reserves and slow response speed. But with rapid development in China, a group of enterprises have caught up and developed DoB ICs. However, the industry, especially traditional power supply manufacturers, has rejected or even suppressed "no power" products, which to some extent hinders the development of this innovative new technology.

DoB IC solution is the future path for LED lighting driven development

Focus on exploring from three aspects:

Standardization, Scaling, Automation

There are many traditional power supply devices, which are large in size and complex in processing, which brings inconvenience to standardization, automation, and large-scale production. According to incomplete statistics, there are currently no less than 20000 LED lamp manufacturers in China. I believe that in the next 5-10 years, there will be over a thousand enterprises. To survive in this fierce competition, improving production efficiency and accelerating automation will be the necessary path. If we still rely on traditional power sources, we will face great challenges.

stability

Due to the large number of components in traditional power supplies, the negative factors naturally increase. Especially, the life of Electrolytic capacitor directly leads to the increase of the probability of LED lamp failure. Although capacitors are used in valley filling to eliminate 100Hz power frequency flicker in DoB IC drivers, there are fundamental differences in specific applications between these capacitors and traditional power supply capacitors. On the other hand, capacitor failure in linear valley filling will not cause dead lights. The failure of capacitors in traditional power sources directly leads to dead lights.

Due to the large number of components in traditional power supplies, the negative factors naturally increase. Especially, the life of Electrolytic capacitor directly leads to the increase of the probability of LED lamp failure. Although capacitors are used in valley filling to eliminate 100Hz power frequency flicker in DoB IC drivers, there are fundamental differences in specific applications between these capacitors and traditional power supply capacitors. On the other hand, capacitor failure in linear valley filling will not cause dead lights. The failure of capacitors in traditional power sources directly leads to dead lights.

Intelligent lighting

In terms of intelligent lighting, linear IC drives have inherent advantages over traditional switch power drives. Traditional power sources can also achieve intelligent lighting, but the cost or system integration cost far exceeds linearity.

Taking a comprehensive look at the above table, regardless of stability, safety, performance parameters, and high cost, DoB linear IC is a cost-effective LED driver solution.

Current issues with DoB IC

1) Low utilization and efficiency of lamp beads

2) Narrow operating voltage range, difficulty in heat dissipation, voltage flicker, and other issues caused by poor linear adjustment rate

3) 100HZ power frequency flicker

4) Single IC drive power is small, up to 9W

If the core issues mentioned above cannot be fundamentally solved, it is difficult to say that the DoB IC driver solution is the future of LED driving.

How to solve the problems with DoB IC?

(1) Improve power efficiency through higher-order segmentation. The core of high-order segmentation is to achieve 23rd order segmented driving through hybrid control of NMOS and PMOS. The 23 stage segmented 23 stage formula here refers not to the traditional physical segmentation of LED light strings, but to the 23 logical states.

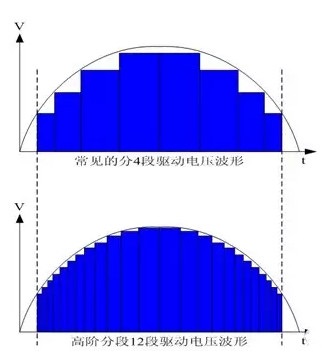

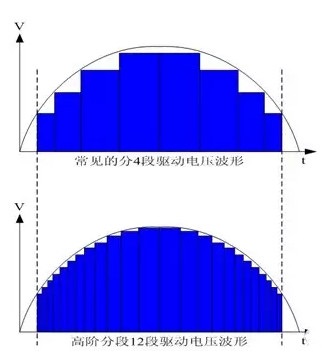

Comparing the common voltage waveforms of 4-segment and higher-order segments here, it can be seen from the figure that the 23-segment driving voltage waveform is almost the same as a sine wave, which improves power efficiency by more than 90%. Therefore, our IC can drive up to 25W.

(2) Dynamic configuration can be summarized in a simple sentence: when the voltage is low, each substring is connected in parallel, and when the voltage is high, each substring is connected in series. This sentence sounds simple, but it took nearly half a year, and we call it ‘dynamic configuration‘. Each sub string of lamp beads is continuously lit at each voltage segment, thereby improving the light efficiency and lamp bead utilization by 10-15%.

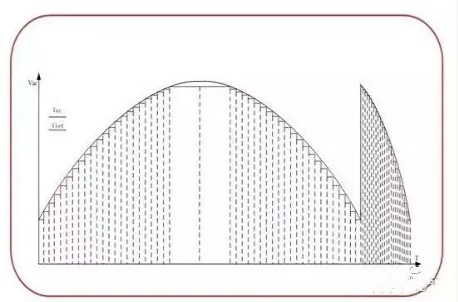

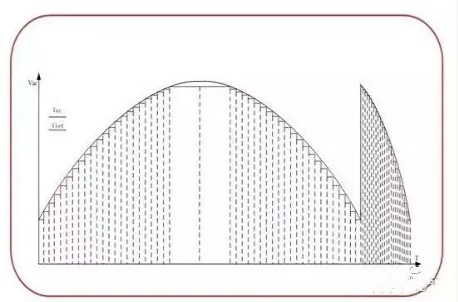

(3) To solve the problem of 100HZ power frequency flicker, active valley filling technology is needed: when the voltage rises, the capacitor is charged, and when the voltage crosses the zero point, the capacitor supplies power to the lamp string. Fully overcome 100%, 100Hz strobe. On these foundations, the lamp bead utilization rate and light efficiency have also been improved by 10-15%.

(4) The poor linear adjustment rate and narrow working voltage are currently important factors hindering the development of linear driving. The power of the lamp increases with the increase of voltage, which is a poor user experience. Through the so-called "dynamic configuration" and "active valley filling", the output power remains basically unchanged under different voltage states, effectively solving the problem of linear adjustment rate difference.

(5) Voltage flicker is a change in light output caused by a wide range of unstable voltage fluctuations. The existing flashover problem has not been resolved yet. The line voltage compensation technology is adopted here. When the voltage fluctuates over a large range, if the DoB IC detects changes in peak voltage and automatically compensates for changes in light output, it can suppress flickering of the lamp caused by voltage fluctuations.

(6) Improve efficiency and heat dissipation technology, with a single drive power of up to 25W.

The innate advantages of DoB IC solution in intelligent lighting

To achieve a smart home, intelligent lighting is indispensable, and without intelligent driving, it is difficult to call it intelligent lighting.

Dimming can be divided into internal dimming and external dimming

The so-called built-in dimming refers to the integrated segmented dimming function within the IC, which achieves fast switching dimming without increasing any power cost or reducing power performance indicators. By switching, it is possible to achieve a three-level dimming function of 100% -50% -10%, as well as color temperature adjustment.

For the so-called external dimming, you can take a look at this architecture: various external sensors such as radar/infrared/voice control module or WIFI/Bluetooth/zigbee module transmit commands to the MCU master chip (possibly included in the wireless communication module), and MCU sends commands to the linear constant current drive chip through SDQ Single Wire Protocol, so as to realize the dynamic change of lamp brightness. Realize various complex intelligent dimming with the lowest system cost and maximum flexibility.

Reasons for the low market share of DoB IC solutions

Firstly, from the perspective of time and development history, the DoB IC solution has only developed rapidly in recent years, which is a new direction and innovation compared to traditional drivers that have been developed for decades. To replace traditional switching power supplies, it requires an industrial validation process.

The second and more important issue is that the core issues of linear IC drives have not been solved yet, and there is still a certain distance in performance compared to switching power supplies. These are all reasons that hinder the development of linear drive and are not widely recognized.

If the existing problems cannot be solved, linear IC driving will always be a trend. It will not be able to replace traditional power drives and therefore cannot become the so-called future mainstream.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |