The boss brings the detailed explanation of the boost converter and discusses the specific products

Time:2022-04-26

Views:2201

Today, Xiaobian will bring you relevant reports on MPS mpq3425 boost converter in this article. By reading this article, you can have a clear understanding of it. The main contents are as follows.

Boost converter, also known as boost converter or boost chopper, is a DC-DC converter that can increase the voltage. Its output (load) voltage will be higher than the input (power) voltage. The boost converter belongs to a switching power supply with at least two semiconductor elements (a diode and a transistor) and at least one energy storage element (inductor). In order to reduce voltage ripple, filters made of capacitors (sometimes with inductors) will be added at the input and output, and mpq3424 is a boost converter.

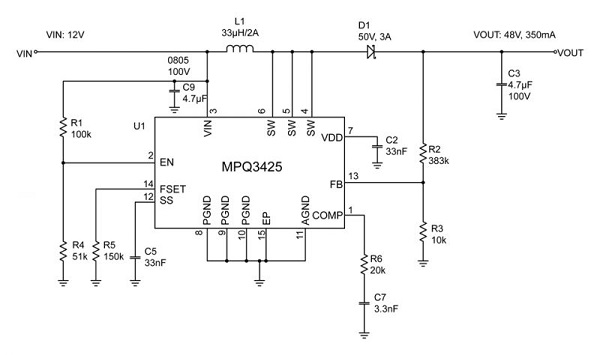

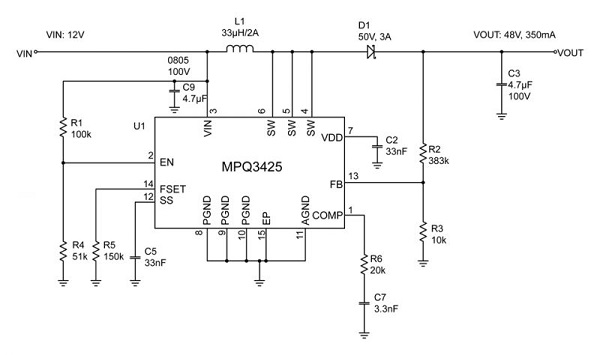

Mpq3425 is a 3.5A, 90m Ω current control mode boost converter with integrated internal switch. It is an efficient regulator with fast response function. The programmable frequency of mpq3425 is up to 2MHz, which is convenient for filtering and low noise design. The external compensation pin can flexibly set the loop dynamics, allowing it to use small-size low ESR ceramic output capacitance. The soft start function provides small surge current and can be adjusted by external capacitance.

The input voltage of mpq3425 boost converter is as low as 3.1V, which can convert up to 48V output voltage and 350mA output current from 12V. Comprehensive protection functions include undervoltage locking protection (UVLO), current limiting protection and thermal overload protection.

Mpq3425 boost converter adopts thin qfn-14 (3mmx4mm) package with heat dissipation pad. The mpq3425 boost converter uses a constant frequency, peak current mode boost regulation architecture to regulate the feedback voltage.

At the beginning of each cycle, the n-channel MOSFET switch turns on, forcing the inductor current to rise. The current of the switching source is measured internally and converted into voltage through the current detection amplifier. Compare this voltage with the error voltage at comp. The voltage at the output of the error amplifier is an amplified version of the difference between the reference voltage and the feedback voltage of 1.225v.

When the two voltages are equal, the PWM comparator will turn off the switch. The inductor current flows to the output capacitor through an external rectifier diode. This causes the inductor current to decrease. The peak inductance current is controlled by comp voltage, which is controlled by output voltage. The output voltage is regulated by the inductor current to meet the load demand. Current mode regulation can improve transient response and control loop stability.

UVLO hysteresis of mpq3425 boost converter

Mpq3425 boost converter has programmable UVLO hysteresis. When Vin is powered on, a 4 µ a current absorber will be applied to the resistance divider connected to en. Therefore, VIN must be increased additionally to overcome current absorption. This additional amount is the current absorption multiplied by the current of the resistor from VIN to en. When en reaches 1.5V, the current absorber closes to produce the reverse hysteresis of VIN drop.

How to select soft start capacitor for mpq3425 boost converter

The mpq3425 boost converter uses a soft start timer that limits the voltage on the comp during start-up to prevent excessive current at the input. This prevents premature termination of the supply voltage at start-up due to input current overshoot.

When the mpq3425 boost converter is powered on and enabled, the 5 µ a internal current source charges the external capacitor at SS. When the SS capacitor is charged, the SS voltage rises. When the SS voltage reaches 250Mv, the mpq3425 boost converter starts switching at a quarter of the set frequency. This is called frequency turn back mode.

At 800mv, the switching frequency changes to the programmed value. When the voltage on SS reaches 2.5V, the soft start ends. This limits the inductor current at start-up and forces the input current to rise slowly to the current required to adjust the output voltage.

How to select the input capacitance of mpq3425 boost converter

An input capacitor is required to provide AC ripple current to the inductor while limiting the noise of the input source. A low ESR capacitor is required to keep the noise of the IC to a minimum. Ceramic capacitors are recommended, but tantalum capacitors or low ESR electrolytic capacitors are also sufficient.

Use an input capacitor greater than 4.7 µ F. Capacitors can be electrolytic, tantalum or ceramic. However, since the capacitor absorbs the input switching current, sufficient ripple current rating is required. Please use capacitors with RMS rated current greater than inductive ripple current.

To ensure stable operation, place the input capacitor as close to the IC as possible. Alternatively, a smaller high-quality 0.1pf ceramic capacitor can be placed closer to the IC and a larger capacitor can be placed further away. If this technology is used, it is recommended that the larger capacitor be tantalum or electrolytic capacitor. All ceramic capacitors shall be placed close to the mpq3425 boost converter.

All the above contents are all the introductions about mpq3425 boost converter brought by Xiaobian. If you want to know more about mpq3425 boost converter, you might as well explore it on our website or Baidu, Google and MPs.

Boost converter, also known as boost converter or boost chopper, is a DC-DC converter that can increase the voltage. Its output (load) voltage will be higher than the input (power) voltage. The boost converter belongs to a switching power supply with at least two semiconductor elements (a diode and a transistor) and at least one energy storage element (inductor). In order to reduce voltage ripple, filters made of capacitors (sometimes with inductors) will be added at the input and output, and mpq3424 is a boost converter.

Mpq3425 is a 3.5A, 90m Ω current control mode boost converter with integrated internal switch. It is an efficient regulator with fast response function. The programmable frequency of mpq3425 is up to 2MHz, which is convenient for filtering and low noise design. The external compensation pin can flexibly set the loop dynamics, allowing it to use small-size low ESR ceramic output capacitance. The soft start function provides small surge current and can be adjusted by external capacitance.

The input voltage of mpq3425 boost converter is as low as 3.1V, which can convert up to 48V output voltage and 350mA output current from 12V. Comprehensive protection functions include undervoltage locking protection (UVLO), current limiting protection and thermal overload protection.

Mpq3425 boost converter adopts thin qfn-14 (3mmx4mm) package with heat dissipation pad. The mpq3425 boost converter uses a constant frequency, peak current mode boost regulation architecture to regulate the feedback voltage.

At the beginning of each cycle, the n-channel MOSFET switch turns on, forcing the inductor current to rise. The current of the switching source is measured internally and converted into voltage through the current detection amplifier. Compare this voltage with the error voltage at comp. The voltage at the output of the error amplifier is an amplified version of the difference between the reference voltage and the feedback voltage of 1.225v.

When the two voltages are equal, the PWM comparator will turn off the switch. The inductor current flows to the output capacitor through an external rectifier diode. This causes the inductor current to decrease. The peak inductance current is controlled by comp voltage, which is controlled by output voltage. The output voltage is regulated by the inductor current to meet the load demand. Current mode regulation can improve transient response and control loop stability.

UVLO hysteresis of mpq3425 boost converter

Mpq3425 boost converter has programmable UVLO hysteresis. When Vin is powered on, a 4 µ a current absorber will be applied to the resistance divider connected to en. Therefore, VIN must be increased additionally to overcome current absorption. This additional amount is the current absorption multiplied by the current of the resistor from VIN to en. When en reaches 1.5V, the current absorber closes to produce the reverse hysteresis of VIN drop.

How to select soft start capacitor for mpq3425 boost converter

The mpq3425 boost converter uses a soft start timer that limits the voltage on the comp during start-up to prevent excessive current at the input. This prevents premature termination of the supply voltage at start-up due to input current overshoot.

When the mpq3425 boost converter is powered on and enabled, the 5 µ a internal current source charges the external capacitor at SS. When the SS capacitor is charged, the SS voltage rises. When the SS voltage reaches 250Mv, the mpq3425 boost converter starts switching at a quarter of the set frequency. This is called frequency turn back mode.

At 800mv, the switching frequency changes to the programmed value. When the voltage on SS reaches 2.5V, the soft start ends. This limits the inductor current at start-up and forces the input current to rise slowly to the current required to adjust the output voltage.

How to select the input capacitance of mpq3425 boost converter

An input capacitor is required to provide AC ripple current to the inductor while limiting the noise of the input source. A low ESR capacitor is required to keep the noise of the IC to a minimum. Ceramic capacitors are recommended, but tantalum capacitors or low ESR electrolytic capacitors are also sufficient.

Use an input capacitor greater than 4.7 µ F. Capacitors can be electrolytic, tantalum or ceramic. However, since the capacitor absorbs the input switching current, sufficient ripple current rating is required. Please use capacitors with RMS rated current greater than inductive ripple current.

To ensure stable operation, place the input capacitor as close to the IC as possible. Alternatively, a smaller high-quality 0.1pf ceramic capacitor can be placed closer to the IC and a larger capacitor can be placed further away. If this technology is used, it is recommended that the larger capacitor be tantalum or electrolytic capacitor. All ceramic capacitors shall be placed close to the mpq3425 boost converter.

All the above contents are all the introductions about mpq3425 boost converter brought by Xiaobian. If you want to know more about mpq3425 boost converter, you might as well explore it on our website or Baidu, Google and MPs.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is infringement or objection, please contact us to delete. thank you! |