TDK Launches a New 2A Peak Current Embedded Motor Controller for Driving Brushless (BLDC) and Brushed (BDC) Motors

Time:2023-07-25

Views:792

• TDK has developed a new embedded motor controller that can output 2 A peak current for driving brushless DC motors (BLDC) and brushless DC motors (BDC)

• Embedded motor control technology aims to provide stronger performance and reliability for automotive and industrial application scenarios

• Suitable for hybrid and electric vehicle heat exchange systems, automotive actuators, small fans and pumps, and passenger air conditioning systems

TDK Corporation is expanding its Micronas embedded motor controller series HVC and launching the HVC 5223C. This is a certified automotive grade first level product with a fully integrated motor controller that can drive small brushless (BDC) or brushless (BLDC) motors with a peak phase current of 2 A. The HVC 5223C adopts a compact 5x5 square millimeter 24 pin QFN package, which is functionally compatible with the HVC 5222C pins. The HVC 5222C has a peak current capacity of 1A. The samples are now available for customer evaluation.

In addition to being able to drive 1A or 2A peak currents, HVC 5222C and HVC 5223C devices will also provide many motor specific analog and digital functions, such as phase comparators, virtual star points, and current detection amplifiers, to achieve sensorless control for a single brushless DC motor, or to drive two brushless motors and various other loads.

The HVC series, including HVC 4x and HVC 5x, has been expanded to seven fully integrated motor controllers with three to six motor outputs, capable of supporting peak currents from 500 mA to 2 A. All devices are equipped with 32-bit ARM ® Cortex ®- M3 CPU core and 32 KB or 64 KB flash options. In addition, all devices are equipped with 12 bit, 1 µ s ADC for various measurements, providing a wide range of options in application scenarios that require precise sensing. The device is also equipped with LIN transceivers and UART, using BSM methods for communication and automatic addressing, which increases their versatility in various applications.

All HVC equipment complies with the AEC-Q100 standard for automotive level temperature certification, and is a solution primarily aimed at compact automotive actuator applications for HEV/EV heat exchange systems** AEC-Q100 certification ensures that the HVC 5223C meets the highest quality and reliability standards, making it a trustworthy choice for automotive and industrial application scenarios.

Glossary

• AEC-Q100: Automotive Application Qualification Standards

• ADC: analog-to-digital converter

• BDC: Brushed DC motor

• BLDC: Brushless DC motor

• CPU: Central processing unit

• Level 1: ambient temperature 125 ℃, working junction temperature 150 ℃

• HVC: High voltage microcontroller

• LIN: Local interconnection network for automotive applications

• QFN: Four flat pinless packaging

• UART: Universal asynchronous transceiver

Main application scenarios**

• Passenger air conditioning system, seats

• Hybrid and electric vehicle heat exchange systems

• Automotive actuators

• Small fan and pump

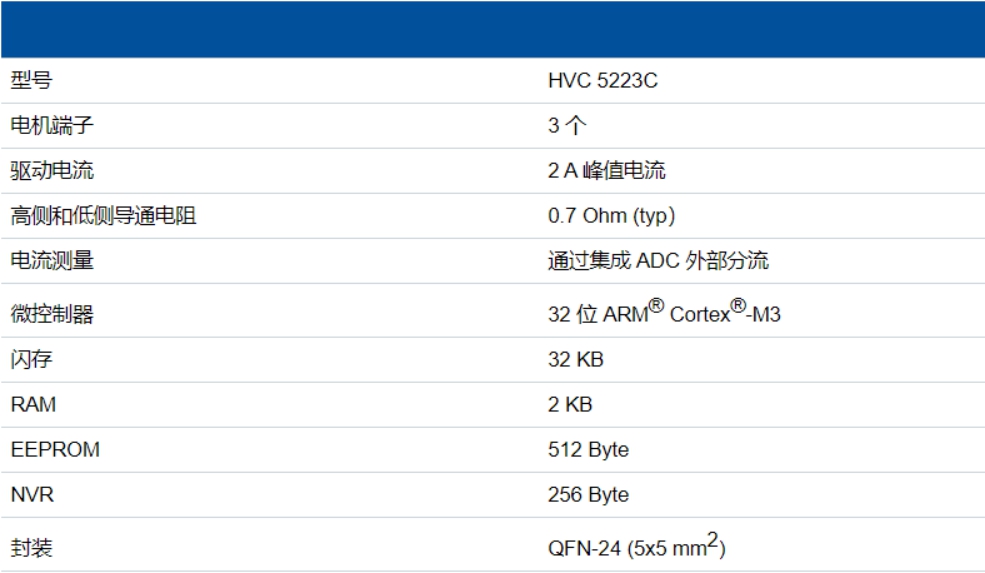

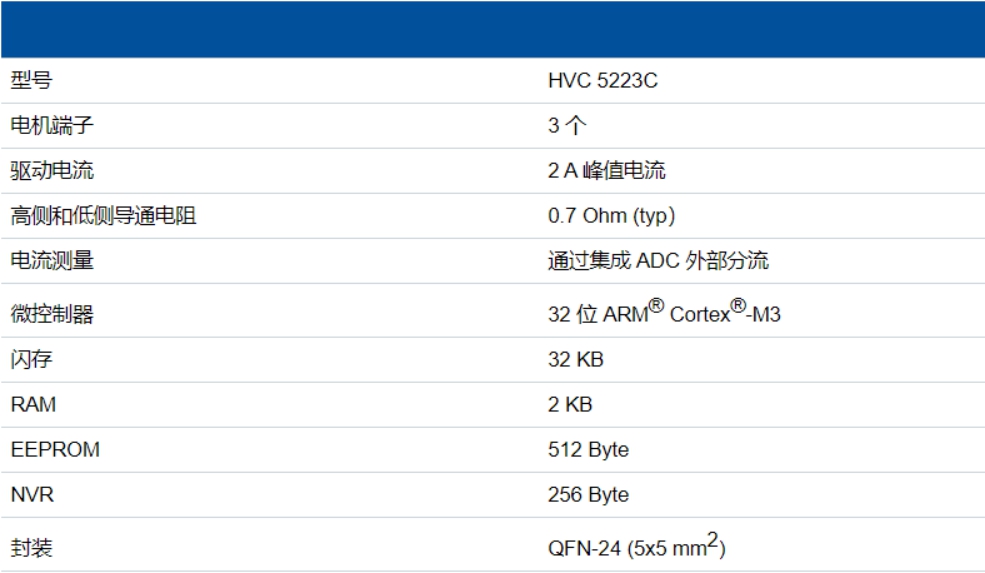

Main data***

*IP prompt: If the LIN automatic addressing function is used, third-party permissions such as EP 1490 772 B should be considered.

**We do not declare that the target application of the product we mentioned is suitable for any purpose, as this must be checked at the system level.

***All operational parameters must be verified by the customer‘s technical experts for each application

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |