Breakthrough of power conversion promotes Robot Revolution

Time:2022-07-06

Views:2001

The innovation of power conversion technology is promoting the reform of robot design. Today‘s integrated power modules are meeting the needs of size, weight, power budget and cost efficiency, thus bringing robots from factories, homes and commercial applications into an imaginary broad Xintiandi.

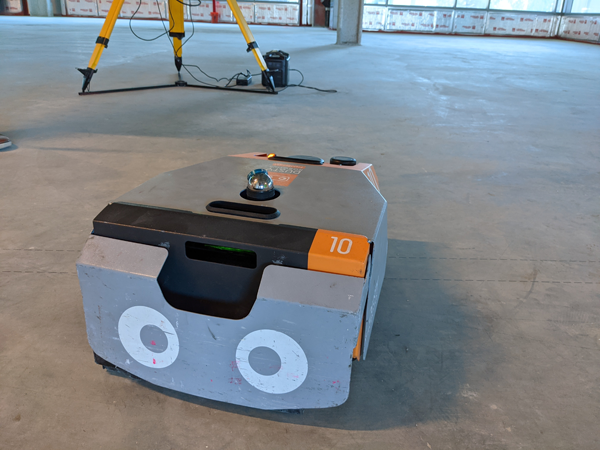

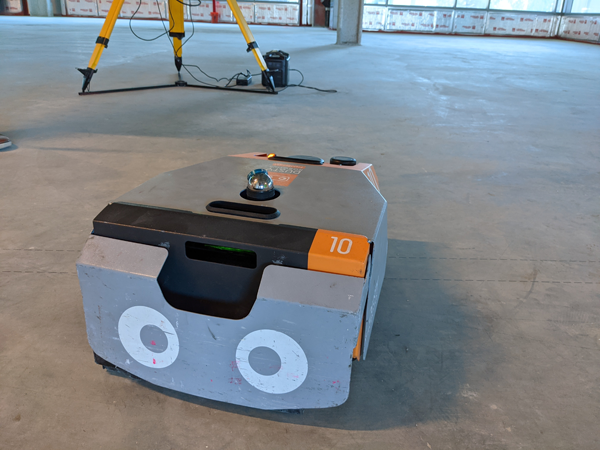

Ogic has designed many different mobile robots for its customers, including dusty Robotics (above). Dusty eliminates the traditional and labor-intensive process of marking the building plan icon on the construction site, and the robot programmed on the construction site can automatically complete this task.

We are at a turning point in history when robots have brought great advantages to our lives. The wide application of robots is of great importance to the company.

Ologic is an electronic design consulting company located in Santa Clara, California. With more than 15 years of rich experience, it helps customers bring large and small robot designs to the market by providing electrical, mechanical and industrial engineering support and software and firmware engineering design. This includes the professional technology of power electronic device integration, which is the main design consideration to determine the working range, functionality and charging capacity of mobile robots.

Ologic has designed a large number of robots for many industries, including agriculture, smart home and inventory control. The robot customer base of ologic can be traced back to a start-up company, which is regarded by many as the pioneer of mobile robots in Silicon Valley. Willow garage is famous for its ability to integrate ready-made open-source software from universities and other entities to help robots perform arduous tasks.

When the company was dissolved in 2014, robot software experts left one after another, and they later founded almost all important robot start-ups in the bay area. This has created a new business for ogic to cooperate with savioke, knightscope, fetch, dusty robotics and other companies.

"The real rock stars in the robotics industry are companies that develop advanced software for businesses such as machine learning or robot algorithm task navigation." Said Ted Larson, CEO of ogic. "Electronic components were added later. As a result, people thought they could buy all these ready-made things and then assemble them. This soon became an unreliable plan."

Robot power supply network case: logic uses VICOR power modules (buck, buck and PRM) in its robots because of their high power density, high efficiency and ease of use. "We use it in many places on mobile robots (VICOR ZVS step-down regulator). I never have to think, ‘Oh, I need 5A or 10A current at 12V voltage, and I want to build my own power supply.‘ I don‘t think so anymore." Said Ted Larson, CEO of ogic.

Give priority to power supply

Mobile robots have unique power challenges that require a range of power levels. The sensors, servo motors, actuators, data servers, communication systems and other equipment of the running robot have different power supply and power density requirements. Some are very power consuming, and some may not run for much time. This requires fast, clean and cost-effective power supply through battery power.

Larson said, "the most used component recently is VICOR ZVS step-down regulator. We have now used it in many parts of mobile robots. I never have to think, ‘Oh, I need 5A or 10A current at 12V voltage, and I want to build my own power supply.‘ I don‘t think so anymore."

Build layout automatically, saving money and time

Dusty Robotics (dusty) is a customer who works closely with logic and optimizes its power configuration. Dusty, headquartered in mountain view, California, manufactures robot driven tools for modern construction workers.

For centuries, the construction industry has used two simple tools to draw architectural plans: tape and chalk lines. Even today, when architects use advanced 3D CAD models to design buildings, the process still needs to print the layout on paper and take it to the construction site for manual annotation. Tape measurement and marking process is slow, prone to human errors, affecting the project progress and budget. Dusty data shows that errors can lead to rework, which usually accounts for 10% of the cost of construction projects.

Philipp Herget, co-founder and chief technology officer of dusty robotics, pointed out: "there will be many errors in manual planning, and the actual errors are even more than the construction industry is aware of. We have heard some cases of construction company bankruptcy caused by layout errors. Dusty robotics can prevent errors, because all annotations are not manually completed, and are completed by robots, which is accurate."

Dusty fieldprinter can increase the speed by five times when it is accurate. Dusty eliminates the traditional and labor-intensive process of annotating building plane icons on the construction site. Robots programmed on the construction site can automatically complete this task. The dusty fieldprinter robot loads the digital plan first, and then prints out various functional layouts on the ground, such as walls, doors, plumbing facilities, and power facilities. It can complete the work within the range of one sixteenth of an inch of the specification at about five times the speed of manual operation.

This innovation makes the construction industry work more like a digital manufacturer, which can not only improve consistency, predictability and reliability, but also improve working conditions for skilled workers who are at the core of the construction process.

Herget said, "if we can shorten the construction period, we can speed up the construction of the building. The sooner the building is completed, the faster the payment will be. Time is money."

With a long battery life and industry-class power conversion technology, dust‘s robot innovation is helping the construction industry realize digitalization, which can create a unique real data source on the construction site based on digital models.

Power the dusty fieldprinter robot

Dusty‘s fieldprinter is a battery powered mobile robot that can work for a long time under various meteorological conditions. It includes a large number of different electronic devices, including sensors, drive motors and electric components, processors with a large amount of calculation, and a printer. All these devices have different working voltage and current requirements.

That‘s why dusty commissioned logic to build core electronic components for its robots. Ologic started with discrete power solutions. But as time went on, VICOR introduced a modular method to ologic to build a power supply network (PDN) for robots. Ologic began to realize that they simply could not design products with high working efficiency and heat dissipation efficiency and a wide working range like VICOR power module. In addition, VICOR modules such as ZVS step-down regulator can also provide 200 ~ 300W power and 97% efficiency, which is very cost-effective.

With its long battery life and industry-class power conversion technology, dust‘s robot innovation is helping the construction industry realize digitalization, which can create a unique real data source on the construction site based on digital models. Now, architects, general contractors and each business partner no longer construct according to their own paper plans, and each unit performs its own duties according to the unified design marked on the construction site. By providing digital layout, we can enhance the coordination among these many partners, so as to improve planning, improve execution and shorten the completion period.

Herget said, "construction automation is enhancing the ability of human beings to transform the world. People used to use screwdrivers, but now they use electric tools. This can greatly simplify work. Our robot driven tools can help the construction industry upgrade and create better results while improving the working environment of skilled workers."

Ogic has designed many different mobile robots for its customers, including dusty Robotics (above). Dusty eliminates the traditional and labor-intensive process of marking the building plan icon on the construction site, and the robot programmed on the construction site can automatically complete this task.

We are at a turning point in history when robots have brought great advantages to our lives. The wide application of robots is of great importance to the company.

Ologic is an electronic design consulting company located in Santa Clara, California. With more than 15 years of rich experience, it helps customers bring large and small robot designs to the market by providing electrical, mechanical and industrial engineering support and software and firmware engineering design. This includes the professional technology of power electronic device integration, which is the main design consideration to determine the working range, functionality and charging capacity of mobile robots.

Ologic has designed a large number of robots for many industries, including agriculture, smart home and inventory control. The robot customer base of ologic can be traced back to a start-up company, which is regarded by many as the pioneer of mobile robots in Silicon Valley. Willow garage is famous for its ability to integrate ready-made open-source software from universities and other entities to help robots perform arduous tasks.

When the company was dissolved in 2014, robot software experts left one after another, and they later founded almost all important robot start-ups in the bay area. This has created a new business for ogic to cooperate with savioke, knightscope, fetch, dusty robotics and other companies.

"The real rock stars in the robotics industry are companies that develop advanced software for businesses such as machine learning or robot algorithm task navigation." Said Ted Larson, CEO of ogic. "Electronic components were added later. As a result, people thought they could buy all these ready-made things and then assemble them. This soon became an unreliable plan."

Robot power supply network case: logic uses VICOR power modules (buck, buck and PRM) in its robots because of their high power density, high efficiency and ease of use. "We use it in many places on mobile robots (VICOR ZVS step-down regulator). I never have to think, ‘Oh, I need 5A or 10A current at 12V voltage, and I want to build my own power supply.‘ I don‘t think so anymore." Said Ted Larson, CEO of ogic.

Give priority to power supply

Mobile robots have unique power challenges that require a range of power levels. The sensors, servo motors, actuators, data servers, communication systems and other equipment of the running robot have different power supply and power density requirements. Some are very power consuming, and some may not run for much time. This requires fast, clean and cost-effective power supply through battery power.

Larson said, "the most used component recently is VICOR ZVS step-down regulator. We have now used it in many parts of mobile robots. I never have to think, ‘Oh, I need 5A or 10A current at 12V voltage, and I want to build my own power supply.‘ I don‘t think so anymore."

Build layout automatically, saving money and time

Dusty Robotics (dusty) is a customer who works closely with logic and optimizes its power configuration. Dusty, headquartered in mountain view, California, manufactures robot driven tools for modern construction workers.

For centuries, the construction industry has used two simple tools to draw architectural plans: tape and chalk lines. Even today, when architects use advanced 3D CAD models to design buildings, the process still needs to print the layout on paper and take it to the construction site for manual annotation. Tape measurement and marking process is slow, prone to human errors, affecting the project progress and budget. Dusty data shows that errors can lead to rework, which usually accounts for 10% of the cost of construction projects.

Philipp Herget, co-founder and chief technology officer of dusty robotics, pointed out: "there will be many errors in manual planning, and the actual errors are even more than the construction industry is aware of. We have heard some cases of construction company bankruptcy caused by layout errors. Dusty robotics can prevent errors, because all annotations are not manually completed, and are completed by robots, which is accurate."

Dusty fieldprinter can increase the speed by five times when it is accurate. Dusty eliminates the traditional and labor-intensive process of annotating building plane icons on the construction site. Robots programmed on the construction site can automatically complete this task. The dusty fieldprinter robot loads the digital plan first, and then prints out various functional layouts on the ground, such as walls, doors, plumbing facilities, and power facilities. It can complete the work within the range of one sixteenth of an inch of the specification at about five times the speed of manual operation.

This innovation makes the construction industry work more like a digital manufacturer, which can not only improve consistency, predictability and reliability, but also improve working conditions for skilled workers who are at the core of the construction process.

Herget said, "if we can shorten the construction period, we can speed up the construction of the building. The sooner the building is completed, the faster the payment will be. Time is money."

With a long battery life and industry-class power conversion technology, dust‘s robot innovation is helping the construction industry realize digitalization, which can create a unique real data source on the construction site based on digital models.

Power the dusty fieldprinter robot

Dusty‘s fieldprinter is a battery powered mobile robot that can work for a long time under various meteorological conditions. It includes a large number of different electronic devices, including sensors, drive motors and electric components, processors with a large amount of calculation, and a printer. All these devices have different working voltage and current requirements.

That‘s why dusty commissioned logic to build core electronic components for its robots. Ologic started with discrete power solutions. But as time went on, VICOR introduced a modular method to ologic to build a power supply network (PDN) for robots. Ologic began to realize that they simply could not design products with high working efficiency and heat dissipation efficiency and a wide working range like VICOR power module. In addition, VICOR modules such as ZVS step-down regulator can also provide 200 ~ 300W power and 97% efficiency, which is very cost-effective.

With its long battery life and industry-class power conversion technology, dust‘s robot innovation is helping the construction industry realize digitalization, which can create a unique real data source on the construction site based on digital models. Now, architects, general contractors and each business partner no longer construct according to their own paper plans, and each unit performs its own duties according to the unified design marked on the construction site. By providing digital layout, we can enhance the coordination among these many partners, so as to improve planning, improve execution and shorten the completion period.

Herget said, "construction automation is enhancing the ability of human beings to transform the world. People used to use screwdrivers, but now they use electric tools. This can greatly simplify work. Our robot driven tools can help the construction industry upgrade and create better results while improving the working environment of skilled workers."

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is infringement or objection, please contact us to delete. thank you! |